Air Compression

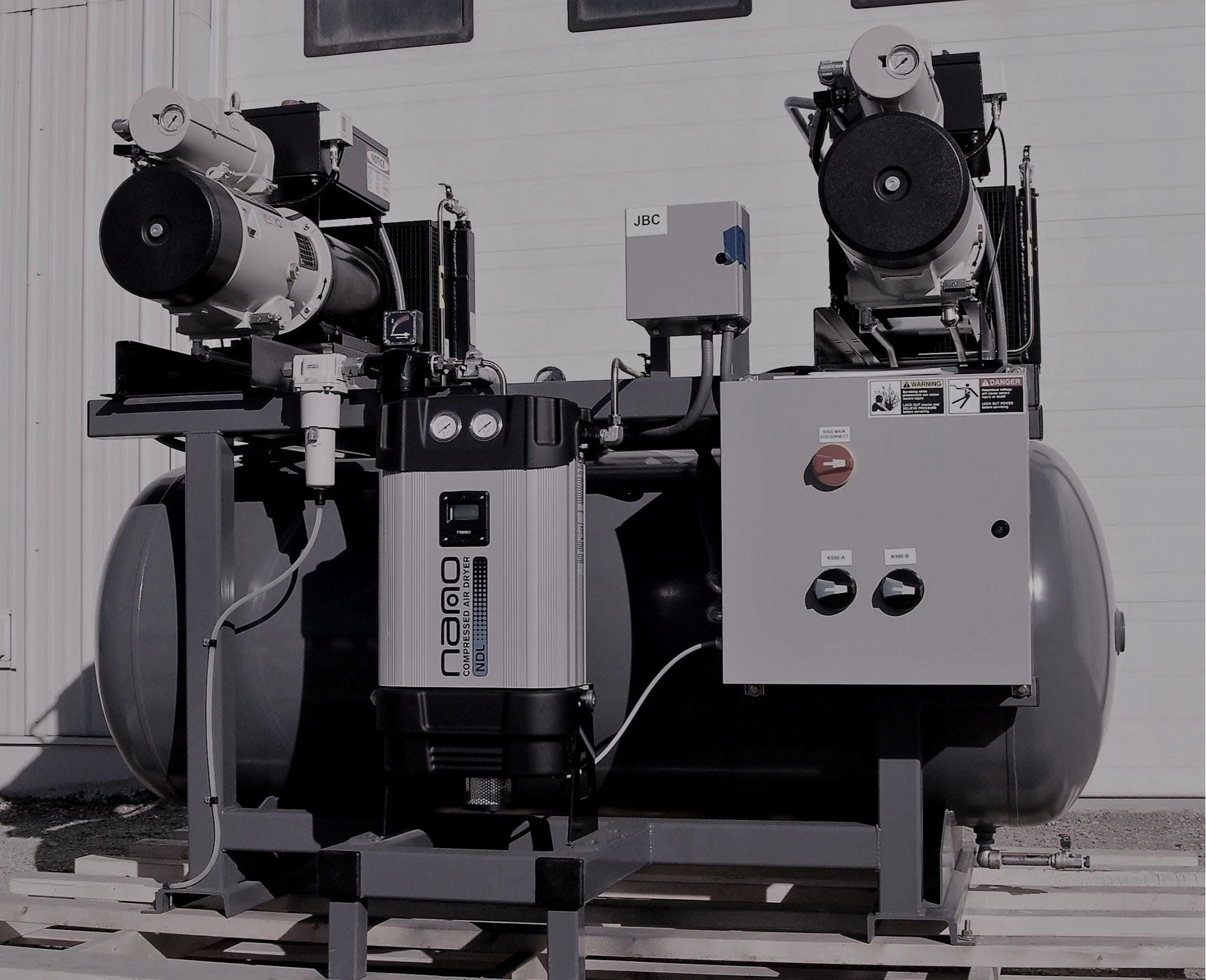

Instrument Air Compressor Packages

Applied Compression offers a full range of compressor packages designed specifically to provide clean, dry compressed air for process and instrument air applications. These instrument air compressor packages are designed and fabricated to meet today’s stringent ISA requirements for instrumentation quality compressed air, with outstanding performance and long-term economy.

You get a completely pre-engineered air system ensuring an adequate supply of clean, dry instrument quality air with a minimum of expense.

Maintaining tightly controlled overhead costs and utilizing specialized out-source partners, allows us to pass significant savings along to our customers, lowering overall costs while maintaining quality and meeting promised deliveries.

We can either supply standard units or if such equipment does not meet your requirements, we can design and manufacture equipment that is custom fabricated from CAD drafting through to final testing. Years of design and manufacturing experience allow us to cost effectively build to special customer requirements.

Medium Pressure Air Compressor Packages (250 – 1000 PSIG)

Applied Compression has an unparalleled reputation in the design and fabrication of medium pressure air compressor packages. We offer one of North America’s largest inventories of compressors suitable for pressures ranging from 250 PSIG to 1000 PSIG.

We are an authorized OEM for Ingersoll Rand model 15T2, 7T2 and 231 compressors and offer a full range of standard and custom designed compressor packages using these blocks.

For those customers looking for a more cost-effective alternative, our Vector 1000 Series compressors offer a part-for-part interchange with Ingersoll Rand 15T2, 7T2 and 231 medium pressure air compressors at substantial cost savings.

In addition, we offer a large stock of competitively priced maintenance and replacement parts for 15T2, 7T2 and 231 compressors.

Our application experience includes:

Ship starting compressors

Oil field engine starting

High pressure circuit breakers

Valve testing

Pressure testing

Inert gas injection

Coil tube testing

Medium Pressure Air and Inert Gas Compressor

(300 – 1000 PSIG)

Applied Compression has an unparalleled reputation in the design and fabrication of medium pressure air and inert gas compressors. We offer North America’s largest inventory of compressors suitable for pressures ranging from 300 – 1000 PSIG.

These compressor packages are available with:

Electric motors

Diesel, gasoline or natural gas engines

Hydraulic motors

Class 1 Div 2 or Class 2 Div 1 compliance

Our application experience includes:

PET bottle blowing

Leak testing

Aircraft ground support

Inert gas compression

Ship starting compressors

Oil field engine starting

High pressure circuit breakers

Valve testing

Pressure testing

Air and inert gas boosting

VECTOR 1000 SERIES COMPRESSORS

2 to 15 horsepower

4 to 31 CFM

Discharge pressures from 300 to 1000 PSIG

Air-cooled

Cost effective direct interchange with Ingersoll Rand models 231, 7T2 & 15T2

North America’s largest inventory

VECTOR 6100 SERIES BOOSTER COMPRESSORS

10 to 40 Horsepower

74 to 413 CFM

Maximum discharge pressure 580 PSIG

Suction pressure range 100 to 190 PSIG

Air cooled

High Pressure Air Compressor Packages (1100 – 6000 PSIG)

If your company requires a high pressure compressor package, we can help.

Applied Compression has a strong focus on high pressure compressed air applications for the power generation, manufacturing, marine, safety and petrochemical industries.

We offer one of North Americas largest inventories of compressors for pressures from 1100 to 6000 PSIG.

Our packages offer a clean, simple design that allows easy access for normal maintenance.

Applications include:

Coil pressure testing

Air blast switch gear

Engine starting

Valve testing

Compressed air energy storage (CAES)

Inert gas compression

High pressure tube testing

Military

Rig tensioning

Ballast control

Brands

Boge Rotary Screw Air Compressors

BOGE manufactures a complete range of lubricated and oil free screw and piston compressors from 1 to 450 HP.

Compressed air is considered the fourth utility and you can find the BOGE product in most industry sectors including, but not limited to, pharmaceutical, food, plastics, steel and wood working.

BOGE now has over 100 years of knowledge, experience and engineering expertise to provide you with the perfect quality compressor formula! BOGE is one of the oldest German compressor manufacturers and is still a family run business, not in its fourth generation, with the great-grandson of the founder, Otto Boge and Managing Director of the Company.

C/CL SERIES

The C and CL Series from BOGE provides a small and quiet screw compressor ideally suited to the smaller industrial compressor user.

The CL Series is noted for its low noise levels which are achieved by using lamellar graphite castings which result in sound pressure levels as low as 59 db(A).

Free air delivery: 12 – 77 CFM

Pressure range: 115 – 190 PSIG

Motor range: 4 – 20 HP

S SERIES

When the award winning S Series range of BOGE screw compressors was launched 17 years ago it provided a revolutionary design concept. In essence it ensures a high level of compressed air efficiency and reliability.

Free air delivery: 131 – 1.250 CFM

Pressure range: 100 – 190 PSIG

Motor range: 50 – 350 HP

Mattei Rotary Vane Air Compressors

Mattei has been manufacturing air compressors since 1919. Since then the company has continually evolved and is now one of the world’s foremost compressor manufacturers and leader in the production of rotary vane compressors.

Mattei rotary vane technology is simple and features a single off-set rotor which is supported by two (2) white metal babbit bushings and rotates at only 1800 RPM or lower. Blades/vanes slide in and out of the rotor to form compression pockets. Zero-wear Meehanite axial treating prevents wear to the stator wall or the cast iron blades that ride on a thin film of lubricant. Backed by a 10 year warranty, the rotor stator unit (RSU) is exceptionally durable and efficient and it is not uncommon to get over 100,000 hours of service life out of our air-ends (RSU) without a rebuilt.

Mattei’s rotary vane RSU is not subject to thrust forces and remains balanced under load as pressure is equalized along the length of the rotor. Mechanical efficiency remains high (~90%) as there is near-perfect sealing. The oil simply services the shaft bushings and provides lubrication for the blades.

Continuous innovation and advanced design capabilities drive the development of Mattei rotary vane air compressors. They are more efficient than other types of rotary compressors with longer operational lives and a lower cost of ownership, thanks to:

Lower rotational speeds

High volumetric efficiencies

No axial bearing loads

No gear box

Low oil change costs

Fewer moving parts

High specific energy efficiency (CFM/HP)

BLADE SERIES

5 to 10 horsepower

17.5 to 39 CFM

115 to 175 PSIG

Cabinet enclosed (61 – 64 dBA)

ERC SERIES

2 to 100 horsepower

5 to 460 CFM

115 to 150 PSIG

Open frame design

AC SERIES

5 to 60 horsepower

34 to 328 CFM

115 to 175 PSIG

Cabinet enclosed (67 – 69 dBA)

MAXIMA SERIES

Low speed 1200 RPM

40 to 200 horsepower

68 to 1135 CFM

100 to 115 PSIG

Cabinet enclosed 61 – 73 dBA

OPTIMA SERIES

Variable speed drive

68 to 1251 CFM

15 to 250 horsepower

100 to 150 PSIG

Cabinet enclosed 61 – 64 dBA

Request A Quote

Our sales team would be happy to work with you to find a solution for your specific needs.